Carbon Fibre Rifle Wrapping

Bringing Carbon Fibre to precision firearms

From our 45,000 Square foot facility in Rotorua, we manufacture carbon fibre and composite components for clients across the globe. We've co-developed custom rifle-wrapping processes with some of the world's best-renowned precision rifle manufacturers.

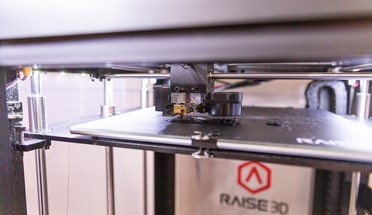

With temperature-controlled preparation rooms, custom-built curing ovens, 3D printing lab, CNC machining centre and an extensive finishing facility, there's not a lot we can't do.

Couple this with a dedicated team of 60 who bring multiple hundreds of years combined experience, and you'll get a sense of the scale and capability Kilwell can offer.

Barrel Wrapping Services

When it comes to carbon fibre rifle barrel wrapping, we've already done the hard yards. From designing material layups to meet your tech specs or desired performance traits, to highly efficient and cost-effective volume production, we have the people, the plant and the process to take your rifles to the next level.

Specialist Capabilities

How can we help?

Keen to team up?

Let us know what you have in mind, and one of our team will get in touch to talk through your project and scope it with you. If you would like to share any drawings now, please do. Or, if you would prefer that we enter in an NDA first, we can make that happen quickly and easily.